QUALITY PHILOSOPHY

● Competition on Quality

● Quality is made by production

● Professional-controllable-traceable-sustainable

● PPAP III /IMDS/ROHS Available

The factory has passed the IATF16949 quality system certification, and has perfect testing equipment, from raw material chemical testing-production process-optical testing-final product testing.

A completed quality system helps to improve the level of quality control management. It is not only reflected on a certificate, but also the most important is certified value and purpose.

The completed tests ensure that the performance of products can meet the established requirements.

And relevant PPAP III documents can be provided, including MSA, SPC, PFMEA, CP and other completed documents.

3D Projector

Material spectrum analyzer

Contourgraph

Universal material testing machine

Metallographic analyzer

Rockwell Hardness Tester

● Competition on Quality

● Quality is made by production

● Professional-controllable-traceable-sustainable

● PPAP III /IMDS/ROHS Available

When a bad product appears, it is very important to find out which batch it belongs to.This is a very important step for customers to determine which batch of products are at risk, so as to minimize the customers’loss and avoid unnecessary work. It also helps to substantially improve the efficiency of the recall and reduce risks.At the same time, it can also judge which program was wrong so that improvement can be carried out in the future production, thus guaranteeing the product high quality.

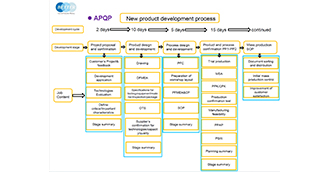

The product development is not only about product knowledge, software analysis, and equipment, also correct and rigorous process analysis before developing, APQP analysis and control plans, prevention measures and solutions.so as to ensure that the product quality can reach the set goal and greatly improved in mass production.

● Goal to "0" Defect

● Optical + Manual sorting 0 defect as the goal

● Foreign Parts

● Not mixed with foreign bodies and impurities

● Product dimension

● Thread

● Hardness