About Better Fasteners

Why BETTER FASTENERS

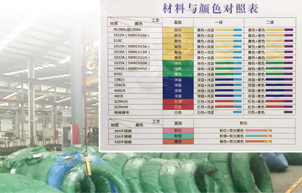

The Choice of Correct Materials

Choosing the right raw materials is the beginning of making high quality products. This is the first step which will affect the next production process.

How to guarantee that the diameters of raw materials meet relevant requirements correctly? This directly affects whether products meet the requirements of original drawings in dimension.

How to control the accuracy of diameters in the drawings is particularly critical.

How to choose the more economical and cost-effective production methods according to order quantities, requirements of surface roughness or special precision? It need professional technology and production experience to analyze and judge in order to ensure high quality of products while guaranteeing it economic and saving cost. Before production, we need carry out the examination and testing for materials. The following is our testing items.

Brand and type identification of steel materials.

- ●Diameter

- ●Roundness

- ●Hardness and tensile strength

- ●Chemical analysis

- ●Smoothness

Selection of Production Technology

No matter which kind of production technology we choose, we have strict manufacturing standards and process control.Every production process has a complete monitoring as well as deviation identification and correction. The less the risk, the higher the quality and more timely delivery.

Professional Fastener Knowledge and Technical Team

With the help of the professional fastening knowledge and experience by BETTER'S technical team, we can better carry out production process.We will evaluate each production process,including development, production, testing, technology and assembly.More importantly, our team understands the special application and quality requirements of each customer.

Quality Control

How to control quality is the segment which reflects the effective value of products. From testing process to final results, it can examine if products have achieved the objective outlined? In order to reduce and avoid human errors, optical sorting equipment is used in inspecting appearance, sizes and thread products.If necessary, we also will distinguish the reception and rejection by manual checking appearance, which will further ensure products quality.

Communication and Service

Good communication and service are important to convey effective information. Ensure every customer’s requirement is known and all subsequent procedures meet the established requirements and quality levels.This process will also reflect the service quality.

Prevention and improvement Measures

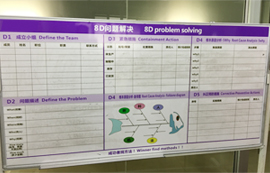

Nothing is absolute. There can be a risk of small probability. A comprehensive and rigorous prevention and improvement measure system is an effective way to prevent possible risks and improve existing issues.

Core Competencies

-

Cold Forging Products

bolts, nuts, screws and customized special parts etc.

-

Precise Machining Products

ultra precision and Microfabrication

-

Precision Stamping Parts

single and compound die Process

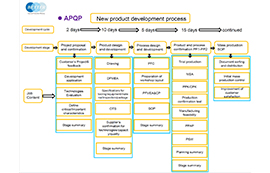

Many industries have designed or put forward special product requirements according to their actual needs.These products are generally not in the market and need original entrusted manufacture based on the actual needs and drawings, which leads to a higher development cost and a longer period.Every new fastener and component need trial assembly to ensure the correct function of the product.

● How to successfully develop special parts and components?

● How to achieve higher quality and fully ensure the function of parts?

● How to control the costs of development and shorten the development cycle?

We have professional fastener knowledge and production experience to help us learn the customers' designs and requirements as well as professional molding analysis software to simulate if the product could be successfully produced. At the same time, APQP feasibility analysis and capacity analysis are also conducted to improve the fasteners’ performance and structural integrity, accuracy of life cycle as well as reflect the cost saving value of each product.

Fasteners are generally used. Its quality level, high or low, good or bad will decide its different performances in function and safety, which fully embodies the importance of fastener’s quality. Where does the quality come from ? Its value lies in the product itself.Quality is not only reflected in QC (quality testing), but in the whole process of production and quality inspection. From raw materials, FAI, process inspection, machining (secondary processing), heat treatment, coating, each process has corresponding management control. Potential failure mode analysis will be carried out in every batch of products to further ensure the high quality of the products.

Every industry must have its professionalization and technicality, measures for improvement and feedback on satisfaction. We pay much attention to requirements and standards for high quality, difficult and demanding components and parts, which can improve the level of our development and research, production, management and technology. It is a process of mutual benefit rather than a simple process of commercial order. Whenever there is negative feedback, we will correct and improve the preventive measures and the production process according to the customers’ requirements. At the same time, the relevant employees will be trained on the targeted improvement measures .Our purpose is to solve the problems and improve the production technology and professionalism so that to meet the needs and requirements of customers.

We will help you to eliminate the complicated procedures, meet your actual needs, ensure the high quality requirements, save the cost, thus to improve the efficiency of customer’s production, so as to reflect the value of our engineering.

Training Procedure

Professional technical, knowledge, operation and other related trainings help to improve work efficiency, product shaping and product quality so as to operate quickly and effectively.It also helps to design and manufacture better products and develop optimized solutions while effectively saving costs.

Engineers and technical experts at Better Fasteners organize all levels of training regularly and continuously.Provide comprehensive professional knowledge and relevant targeted business training to meet the requirements of each customer and ensure that each operation is faster, more professional and more effective.

Training content:

- ● Basic fastener knowledge and standard training

- ● Mechanical performance training

- ● Chemical analysis training

- ● Materials and grades training

- ● Heat treatment training

- ● Product color training

- ● Thread and the precision training

- ● Production engineering and process training

- ● Hydrogen embrittlemen

- ● MSA and SPC

- ● Cost control of fasteners and machining parts

- ● Custsomer communication and service

- ● Emergency plans for customers' special needs

- ● CPK and PPK PPM values

- ● Traceability and controllable of products

- ● Audit and management of suppliers

- ● DASefects Analysis System

- ● Corrective and preventive action

- ● Risk prediction and planning

- ● KAN BAN Training