Cost-optimized solutions

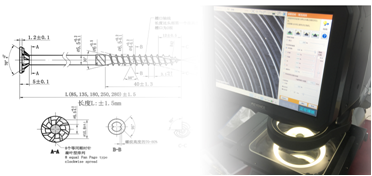

Drawing specitications

Software analysis of product formation

Analysis of fastening system

Technical Approach To Fastening

Product application test

Standardization of products

Technical seminar

Evaluation of assembly lines

Products and industry training

Locking 、Sealing、Masking-Solution applied to prevent loosening and falling off

Lubrication、Anti-Seize、Assembly retention-Improve the efficiency of product assembly

Special anti-corrosion coating-Special coatings can provide more suitable antirust protection

Thread Protection-Improve thread fastening performance

Anodizing-Improve the protection, decoration and insulation of products

Lightweight Solution-Reduce the weight of the product while ensuring the same performance

Stable friction Co-efficiency and Clamp Load -Improve more stable assembly performance

Application of high corrosion resistance and high temperature resistance materials- Used in special high temperature and corrosive environment

Class 14.9/14.9 level of product requirements-Apply to higher demanding environments with mechanical properties

Ultra Precision & Microfabrication -Every minor tolerance determines the perfection and completeness of the assembly and ensures the functionality.

Optical Sorting-PPM -The selection of product appearance, size, thread and so on can further ensure 100% quality level