From the initial product designs to the subsequent application of technology, our engineers will use advanced technical software, including 3D, CAD, molding design analysis and rich experience to design ,reduce costs of development and develop qualified products for final users.We prove our products valuable,which are worth more

than their own prices.Our goal is to develop high quality products and ptimized solutions for our customers.In the manufacturing process, by improving the production process, eliminate the extra cost and improve the efficiency of assembly.We will keep your engineers focused on their next innovation.

For decades, cold forming process has been applied to 5 and 6 stations cold forming equipments, and we cooperate with suppliers to develop professional devices or inspection tools for special processes or manufacturing.Our goal is to make special parts in place at one time so as to improve

the production efficiency, reduce machining processes and costs.The operation efficiency and product competitiveness have been greatly improved.We can make production with the diameters of metal wires from 3mm to 24mm, including carbon steel, stainless steel, aluminum, copper and other common materials.

6 axis high precision machining lathe has capabilities of Drilling, Plane Milling, Contour Milling,Fine Boring, Fine Reamer, Rigid Tapping, Exterior Fine Turning.Inner Hole Fine Turning and Multi-Face Machining .To ensure high accuracy and precision processing, we combine the cold forming technology to reduce the processing costs

and enhance the competitiveness of products.

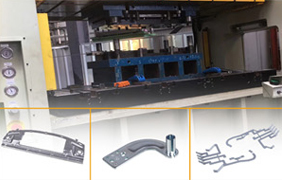

Based on the plastic deformation of the metal, the die and stamping equipment are used in press sheet to put pressure on the plastic deformation or separation, for a certain shape, size and performance of components.We are specialized in manufacturing progressive die and transmission die process to provide

customers with stable batch products, which can achieve the most accurate dimensional accuracy and straightness tolerance.

Heat treatment is one of the key processes in fasteners production. It is the process of changing physical properties by quenching / carburizing and tempering.For many products, heat treatment is the only way to obtain the required mechanical properties. The temperature control, time, carbon potential and operating speed

in heat treatment are of vital importance. Its processes are fully automated and controlled by the computer.

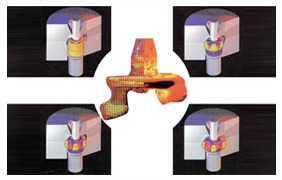

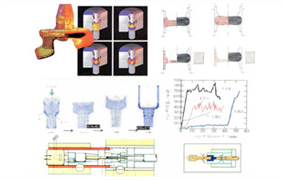

Application Testing

Assembled Analysis

Mold forming Analysis

The simulation software of cold forging can be simulated and analyzed first to reduce the time of mold test and improve the probability of product formation and

effectively improve the efficiency and quality level of production.The accuracy of the analysis can directly affect the initial quality level of the product, so as to meet the requirements of FAI in accordance with the original drawings.